nguyen.eli@outlook.com ⨳ 571-284-8066

The Tempest

GMU School of Theater

Within the technological setting of the show, I wanted to create a dichotomy between the 'high-tech' Ariel and 'low-tech' Caliban. For Caliban, I wanted to lean into the idea that if Ariel is high-tech, sleek, modern technology, then Caliban is like an outdated automaton, rotting away on a tropical island for decades.

Original hand design by @cardboardcraftkazu

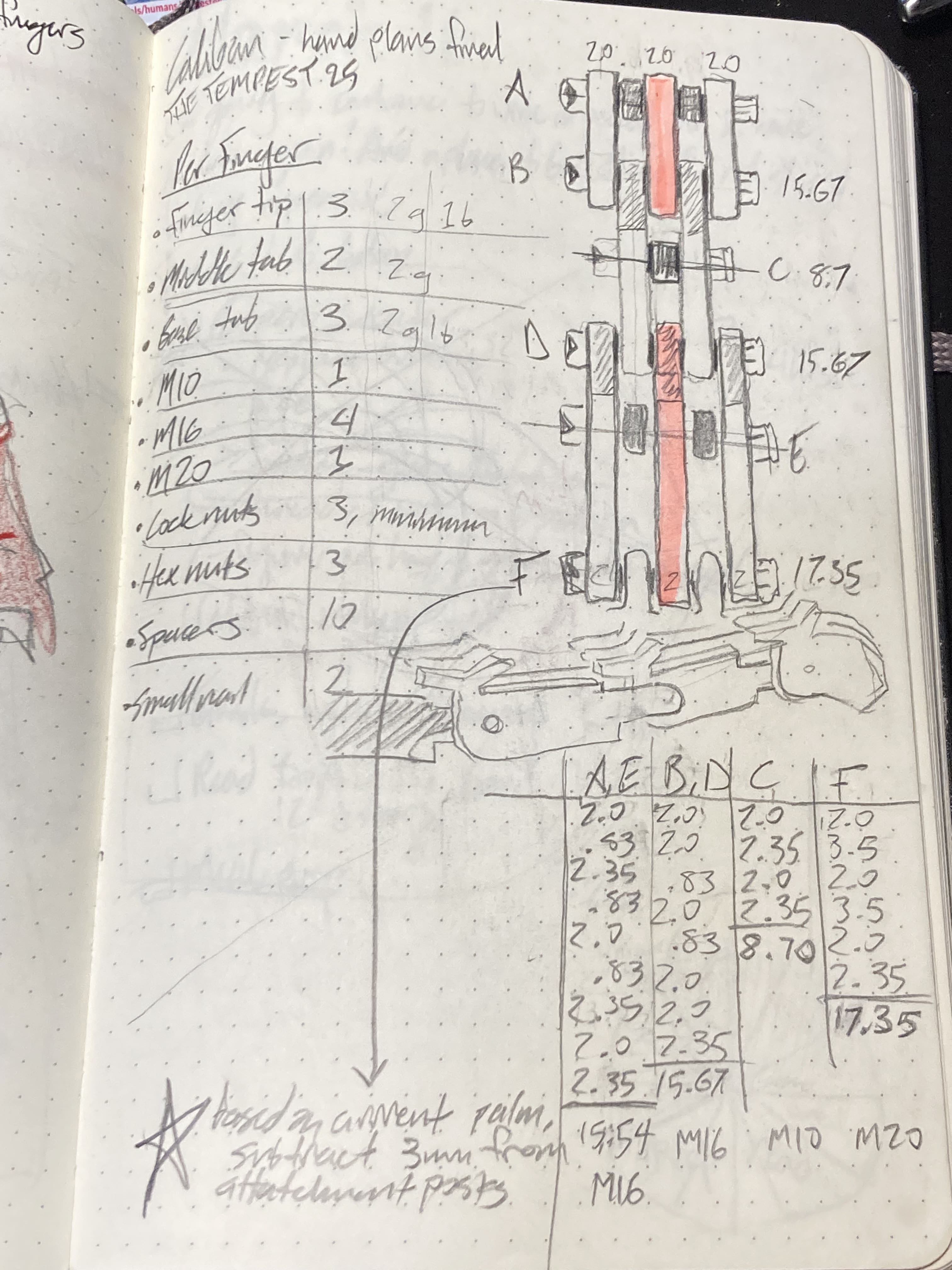

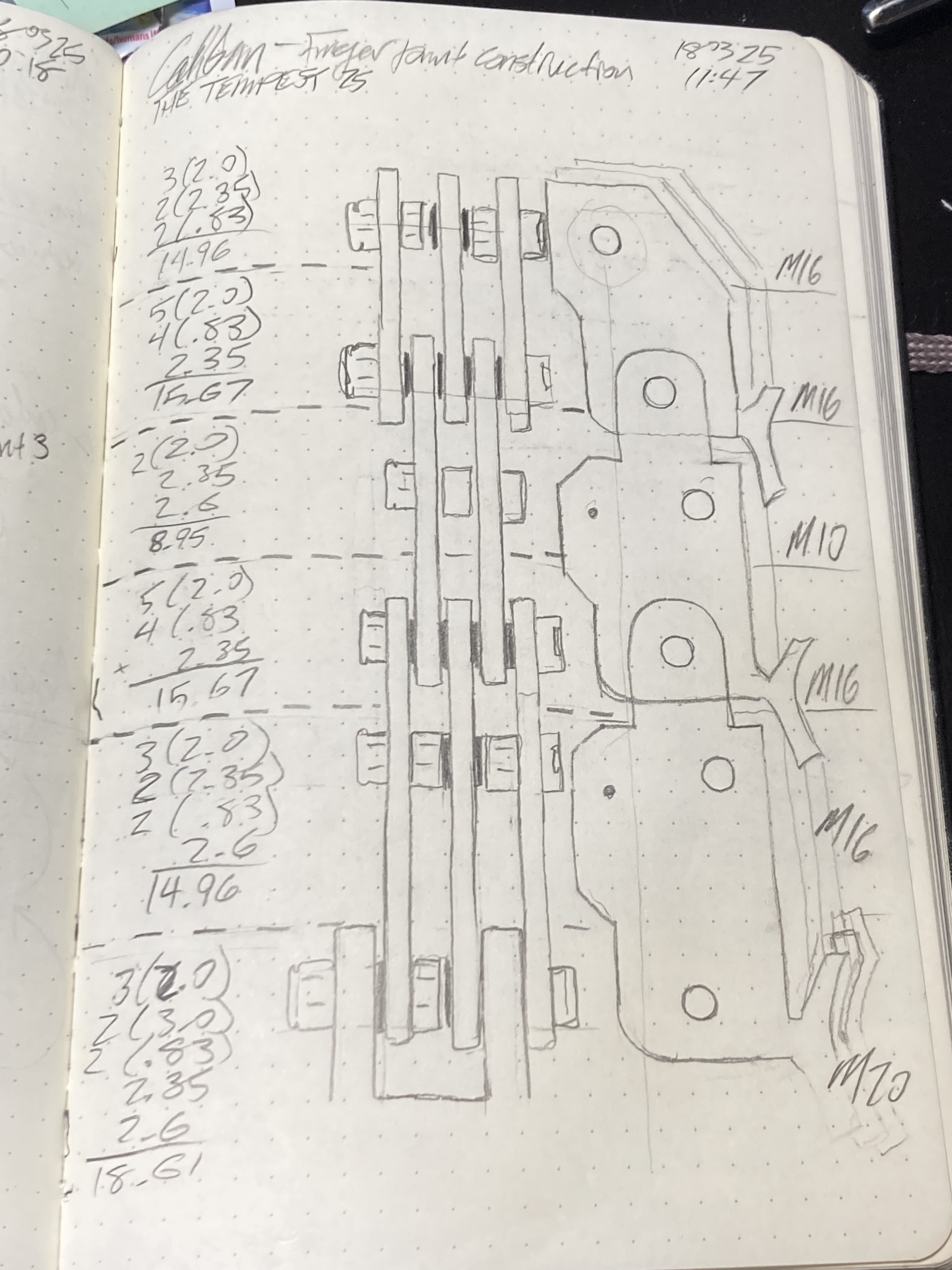

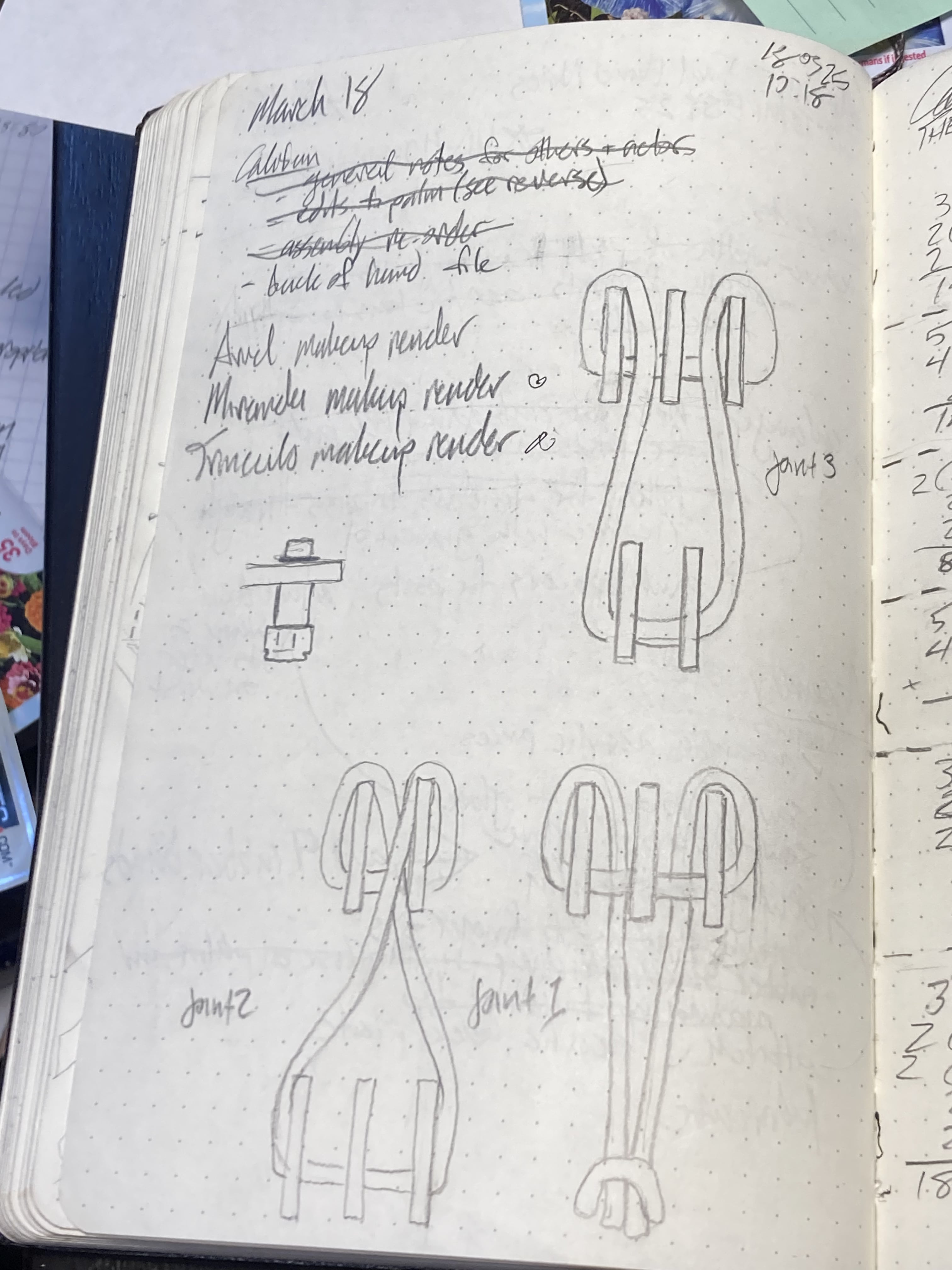

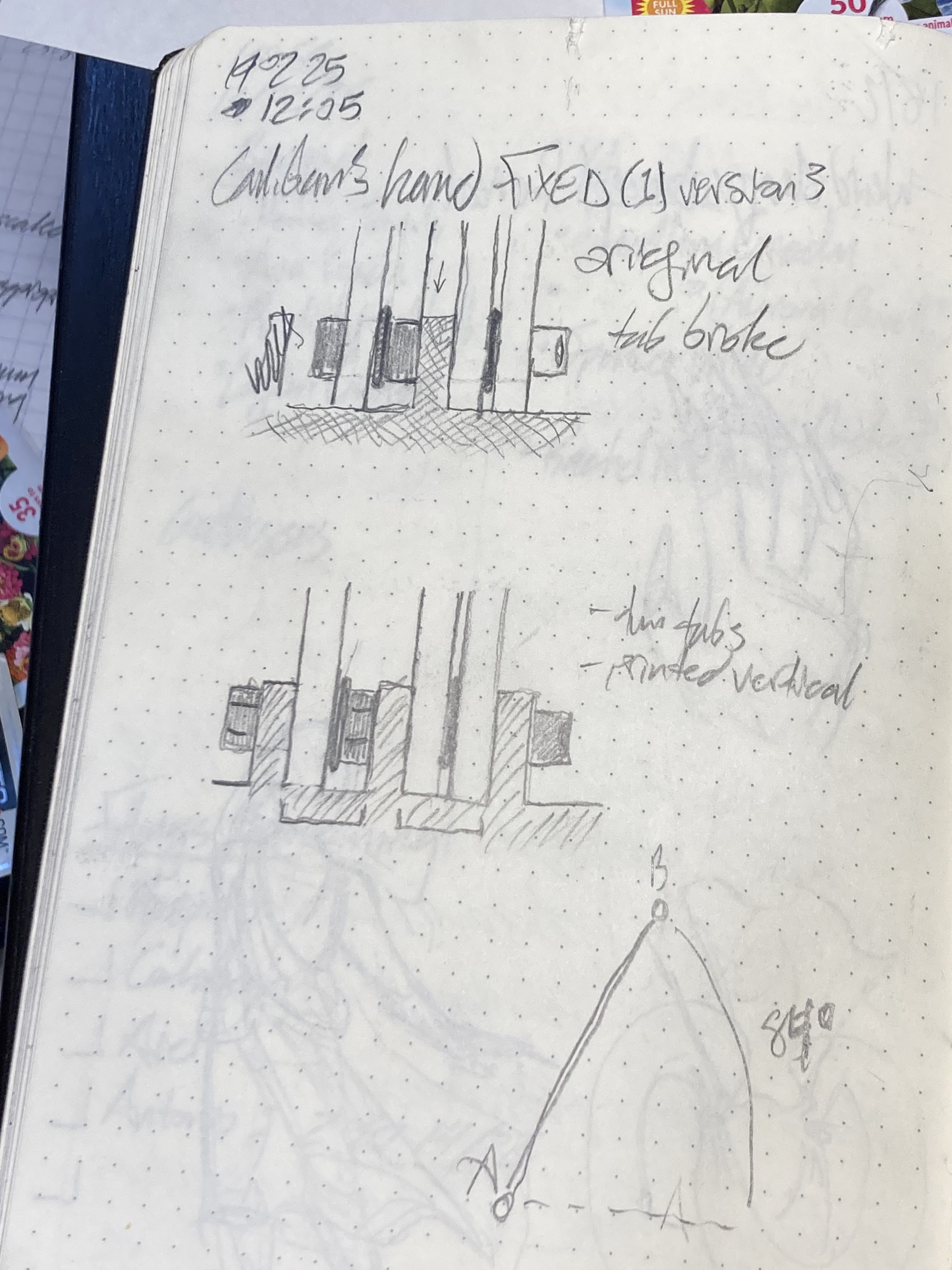

My biggest (completely self inflicted, to be fair) enginnering challenge for this show was creating Caliban's mechanical hand. I wanted to emphasize the automaton-ness of Caliban by giving him a physical technological element, to contrast Ariel's ephemeral digital conjuration. I started with a premade design, and went through ~12 different prototype iterations before finally reaching a design that worked consistently, and achieved the visual effect I was looking for. The fingers and back plate are laser-cut acrylic, attatched to a 3d printed gauntlet, which is sewn to a fingerless work glove, which itself is sewn to a cheap orthopedic wrist brace. The brace stabilizes the weight of the hand so that it doesn't shift or slide when worn. There are 'tendons' running throught each finger made of a piece of 3/8" twill tape, which are sewn to each finger of the glove. This allows the mechanical fingers to move in sync with the actor's own gestures. Each joint is tensioned with heavy duty rubber bands so that the fingers snap back into an open position. The acrylic pieces are screwed together with standard M3 nuts and bolts.

Retrospectively, I don't remember why I went with a fingerless glove over a full-finger glove. It would have solved a lot of the issues I was having with the glove not fitting closely enough for the 'tendon' to activate properly. I solved this on the fingerless glove by ladder stitching each finger to decrease the diameter and the amount of play between the finger and the glove, but I don't think that I would have had that issue if I had started with a normal glove.

For a few weeks my entire world was Caliban's fingers. I carried a tote bag of spare fingers that I was constantly tinkering with and replacing snapped pieces. It took several modifications to the original design to make them work in acrylic instead of cardboard, and many more broken and snapped fingers to figure out what the proper rubber band tensioning needed to be. I used WD-40's silicone lubricant to keep the joints moving smoothly, and found that it was a good compromise between the sewing machine oil I tried initially and dousing them in motor oil (for lack of a better lubricant at the time)

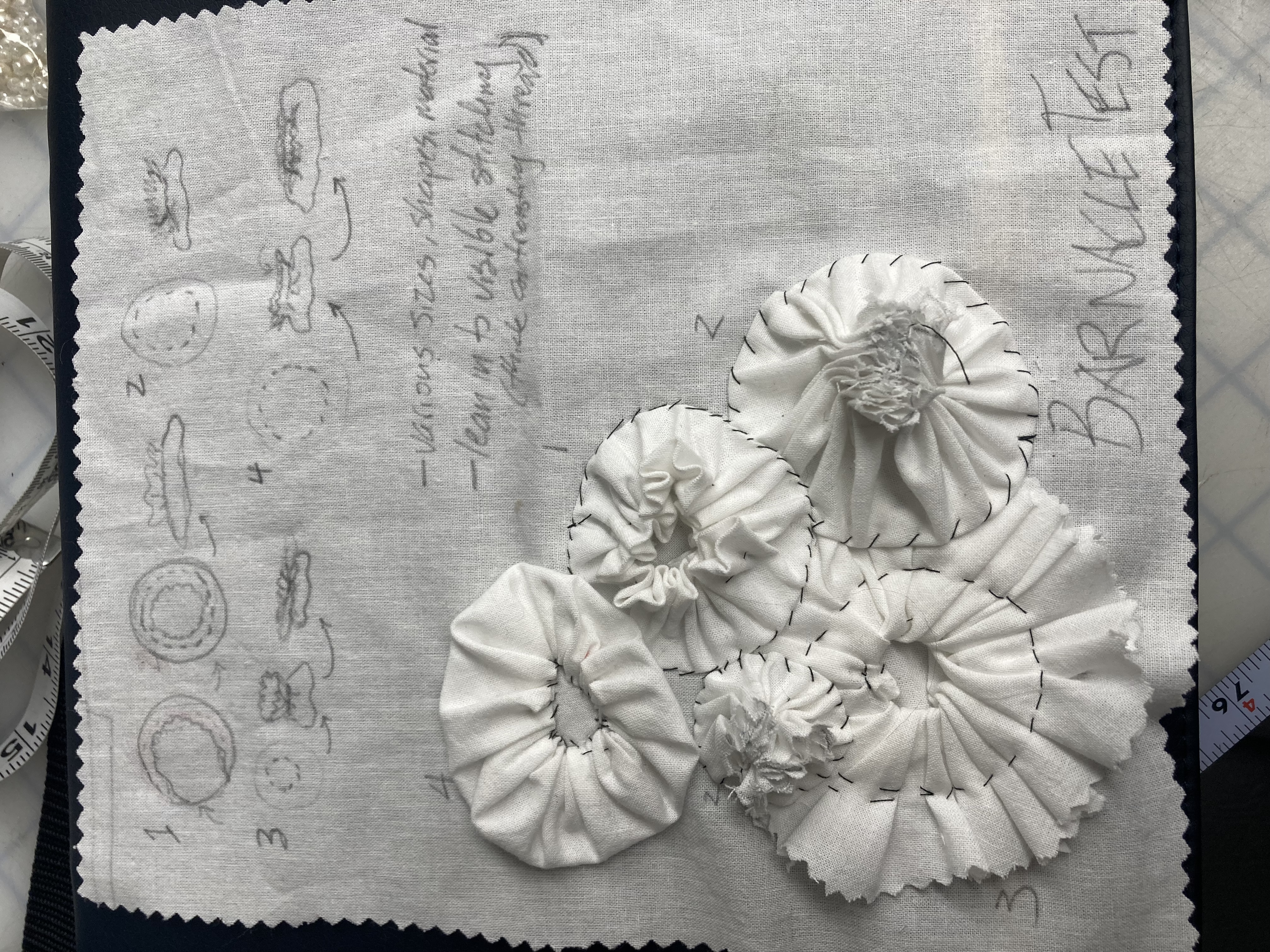

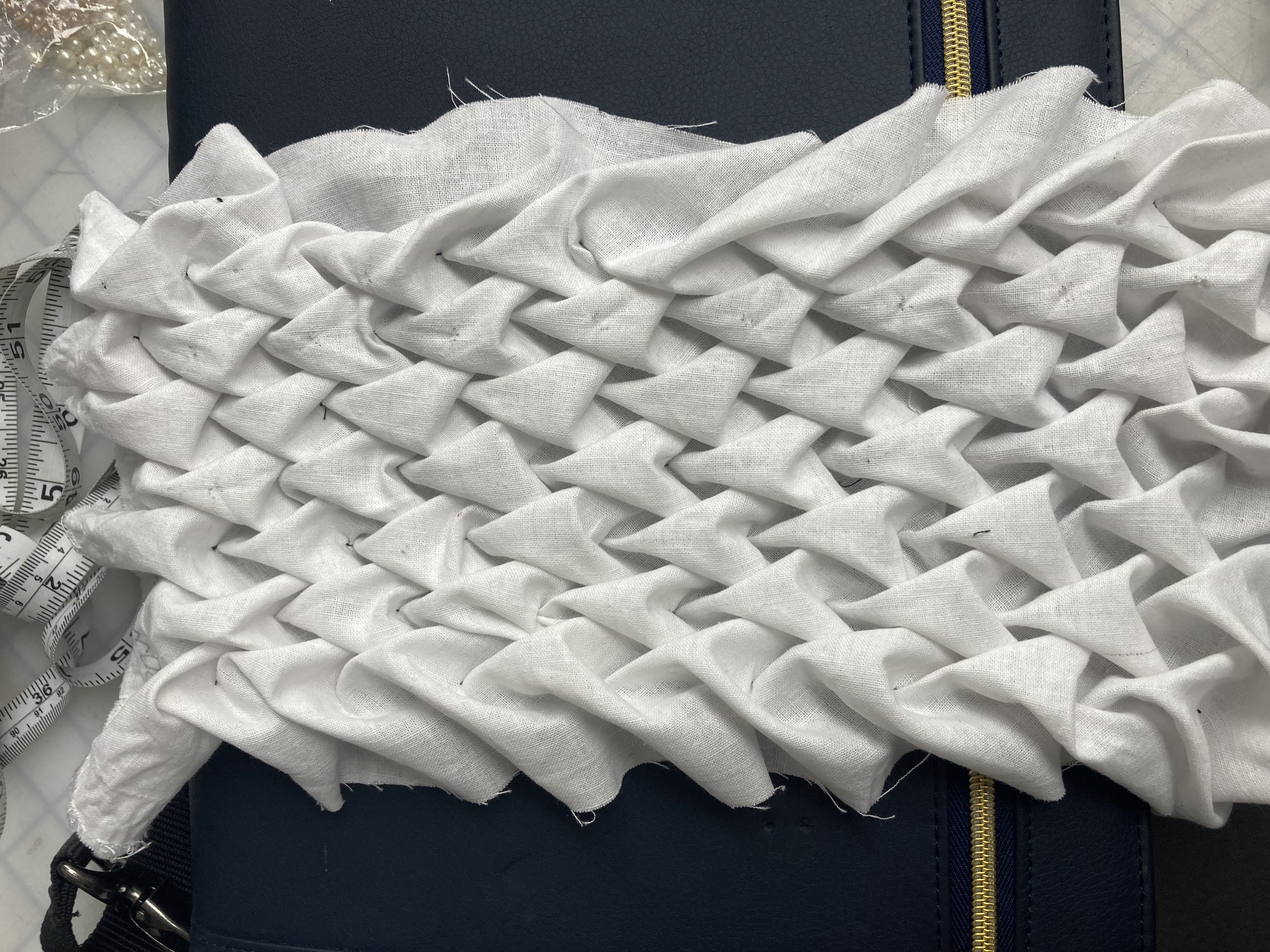

I wanted to evoke the fish-like descriptions of Caliban without being too literal. I was inspired by the way that fabric manipulation techniques like smocking and shirring created scale-like effects. The collar of the jumpsuit, barnacles, and the undershirt were all created with these techniques. The idea for the mask seen in the rendering was discarded early on, both to make Caliban more distinct from Ariel, and also to allow the actor to fully articulate the character.

GET IN TOUCH